How does preventive maintenance ensure workplace safety?

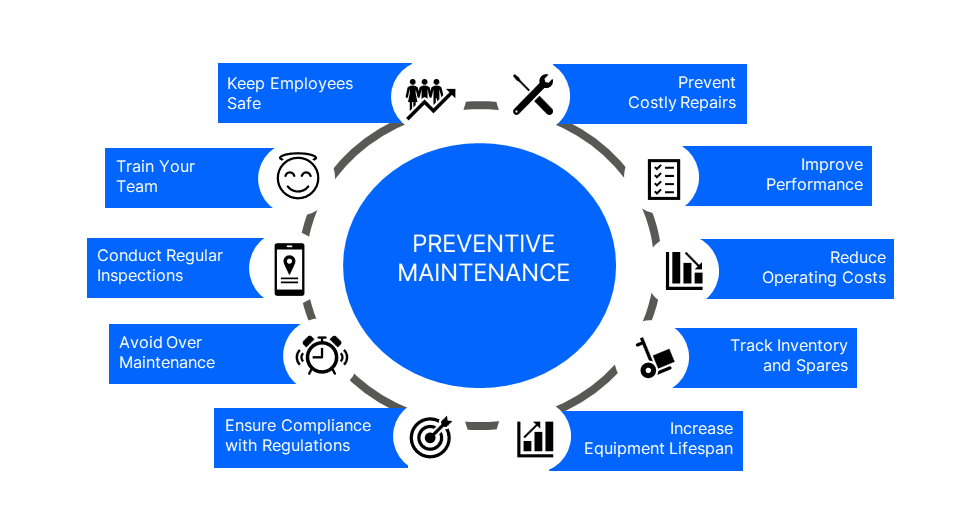

Preventive (or preventative) maintenance is essential for upholding the seamless functioning of facilities and equipment. It reduces downtime and mitigates the risk of accidents or injuries to employees. Furthermore, it contributes to extending the lifespan of facilities, equipment, and assets, resulting in significant time and cost savings by preventing costly repairs or replacements. Effectively managing facilities and assets entails prioritising preventive maintenance as a fundamental aspect.

By treating safety and maintenance as equal partners in this integrated approach, not only reduces incident rates but also cultivates an environment where safety flourishes across the board.

Proper training on equipment usage, regular maintenance of facilities and machinery, and adherence to safety protocols are essential to workplace safety. Additionally, providing personal protective equipment and maintaining a clean and organised workspace can significantly reduce risks. Regular safety audits and feedback mechanisms also help in identifying potential hazards and improving safety measures.

Enterprise Asset Management (EAM) Systems can play a crucial role in preventing workplace injuries and fostering a safe environment in several ways

Equipment Reliability

Regular maintenance helps identify and address potential issues with equipment before they become safety hazards. By ensuring that machinery and tools are in good working condition, the risk of failures or breakdowns that could lead to accidents is significantly reduced.

Maintenance Scheduling

EAM Systems can schedule regular maintenance checks for equipment, ensuring that machinery is always in optimal working condition, reducing the risk of malfunctions that could cause injuries.

Asset Tracking

By tracking the usage and condition of assets, EAM Systems can identify equipment that may be nearing the end of its lifespan or showing signs of wear and tear. This allows for timely replacements or repairs, preventing potential hazards.

Compliance with Regulations

Many industries are subject to safety regulations and standards that require regular inspections and maintenance of equipment. By adhering to these regulations through preventive maintenance activities, businesses can ensure that their workplace meets safety standards set by regulatory authorities. EAM Systems can help ensure compliance with safety regulations and standards by maintaining records of inspections, certifications, and safety protocols. Regular audits can be conducted to identify and address any non-compliance issues.

Asset Verification

Performing physical asset audits is essential for several reasons. It ensures that the assets listed in the records actually exist physically in the specified locations.

Accuracy of Asset Records: It helps in maintaining accurate records of the assets owned by the organisation by updating any changes or discrepancies found during the audit process.

Asset Valuation: Audits help in determining the current value of assets, which is crucial for financial reporting and decision-making processes.

Risk Management: Regular audits help in identifying any potential risks associated with the assets, such as theft, damage, or misuse, allowing for timely mitigation measures.

Compliance: Audits ensure compliance with regulatory requirements and internal policies regarding asset management and reporting.

Resource Optimisation: By identifying underutilised or surplus assets, organisations can optimise resource allocation and reduce unnecessary costs.

Decision Making: Accurate asset data resulting from audits provides valuable insights for strategic decision-making regarding acquisitions, disposals, and maintenance plans.

Training and Certification Management

Preventive maintenance activities provide valuable opportunities for employees to receive training on equipment operation, maintenance procedures, and safety protocols. Professionally trained employees are better equipped to identify and address safety concerns in the workplace. EAM systems can track employee training and certifications related to equipment operation and safety procedures. Ensuring that employees are professionally trained and certified can reduce the risk of accidents.

Emergency Preparedness and Risk Assessment

Regular maintenance helps identify potential weaknesses in equipment or facilities that could lead to emergencies, such as fires or chemical spills. By addressing these issues proactively, businesses can improve their emergency preparedness and response capabilities, enhancing workplace safety. EAM systems can facilitate risk assessments by providing data on asset performance, maintenance history, and usage patterns. This information can help identify potential risks and prioritise safety measures accordingly.

Incident Reporting and Analysis

EAM systems can streamline the process of reporting and analysing workplace incidents. By quickly identifying the root causes of accidents, preventive measures can be implemented to avoid similar incidents in the future.

Communication and Collaboration

EAM systems can improve communication and collaboration among maintenance teams, safety officers and other stakeholders. This ensures that everyone is on the same page regarding safety protocols and preventive measures.

Continuous Improvement and Feedback Loop

Establishing a continuous improvement process that incorporates feedback from employees and maintenance activities is essential for refining preventive maintenance strategies over time. By analysing the effectiveness of preventive maintenance actions and adjusting maintenance plans based on feedback, organisations can continuously optimise their maintenance practices to maximise asset reliability and safety.

In conclusion

Establishing a strong link between maintenance and safety requires the development and widespread communication of a comprehensive plan. Overall, preventive maintenance not only helps keep equipment running efficiently but also plays a crucial role in creating a safe work environment for employees. By integrating these features and functionalities, EAM systems can significantly contribute to creating a safer workplace environment and reduce the risk of workplace injuries.