Organisations across all sectors seek to optimise operational efficiency, leverage data insights, and maintain a competitive advantage. To do this, they need systematic approaches to preserve critical assets and prevent unnecessary replacement costs.

But doing this manually with spreadsheets or with disparate systems can lead to inefficiencies, costly breakdowns, and compliance risks. Consolidating the data from disparate systems and then transforming it into actionable insights that foster organisational change becomes a headache.

That’s where Enterprise Asset Management (EAM) software comes in. By centralising asset data into a single source of truth, automating workflows, and delivering real-time visibility, EAM software not only streamlines operations but also directly contributes to a healthier bottom line.

Boost ROI and efficiency with EAM software

The Return On Investment (ROI) from EAM systems extends far beyond basic maintenance tracking. Modern EAM solutions deliver measurable financial benefits across multiple dimensions of asset-intensive operations. From buildings and machinery to IT equipment and vehicles, these assets that power your organisation are required to be properly maintained and tracked.

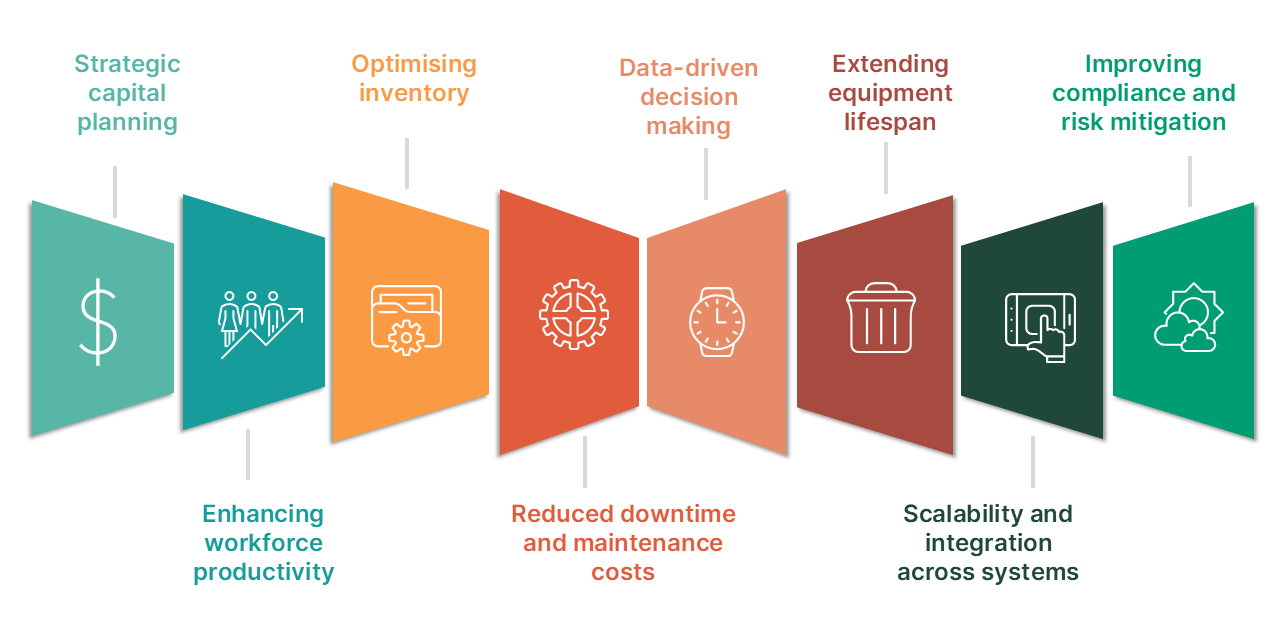

EAM platforms elevate how organisations manage their physical assets. The following analysis highlights key areas where EAM implementations generate substantial ROI.

In this article, we’ll explore how EAM software boosts ROI for enterprises—supported by industry research and real-world examples that demonstrate the tangible value these systems bring to enterprises across sectors.

- Consolidating the data

- Reduce downtime and maintenance costs

- Extending equipment lifespan

- Improving compliance and risk mitigation

- Optimising inventory

- Enhancing workforce productivity

- Strategic capital planning

- Data-driven decision making

- Scalability and integration across systems

Consolidating the data

This is a major challenge many organisations face when trying to integrate and derive value from multiple disconnected systems. Common data management challenges are:

- Data exists in separate, disconnected systems

- Consolidation is difficult but necessary

- Transforming raw data into meaningful insights requires additional effort

- Using those insights to drive organisational change adds another layer of complexity

This is a pain point that resonates across many industries dealing with data silos and digital transformation initiatives. According to our research it’s fair to say that data quality is still generally considered poor. Data continues to be produced in differing formats, across multiple systems and stored in disparate silos, making it extremely difficult to manage and govern.

Organisations are struggling to clarify what and how much data needs to be captured well before it’s cleaned and standardised. Only then will they be able to successfully count on its analytics to generate meaningful insights.

Reduce downtime and maintenance costs with EAM software

Back in the 1930s, maintenance was a “wait ’til it breaks” kind of deal. Machines were either fixed after they failed or given a bit of attention here and there, more guesswork than strategy.

Fast forward to today, and things have changed a lot. Now, most organisations aim to fix equipment before it fails. It’s all about timing, minimising downtime, avoiding sudden breakdowns, and keeping maintenance costs under control.

This is where EAM solutions enter the picture. Modern EAM tools gather maintenance data from multiple sources, consolidates and looks at historical performance. With all this info in a single source of truth, organisations such as healthcare can make smarter, data-driven decisions that align with their goals and risk tolerance.

Unplanned downtime costs manufacturers an estimated $50 billion annually, according to Deloitte. Equipment failures can bring operations to a halt, costing thousands, or even millions in lost productivity and emergency repairs.

EAM software enables predictive and preventive maintenance strategies by:

- Monitoring asset conditions in real-time.

- Scheduling routine maintenance based on usage or time intervals.

- Alerting technicians to potential issues before they escalate.

Example ROI impact:

A global manufacturer achieved a significant operational improvement by implementing preventive maintenance through Hardcat’s Enterprise Asset Management (EAM) software, resulting in a 30% reduction in downtime. This reduction translated into substantial cost savings exceeding $250,000 annually by minimising lost production.

This success illustrates the value of Hardcat’s EAM platform, which enhances proactive maintenance strategies by using data-driven tools to predict asset failures before they occur. Through continuous monitoring integration and insightful analytics, the EAM system helps manufacturers optimise maintenance schedules, ensure timely servicing, and avoid unexpected breakdowns that disrupt production lines.

Key benefits contributing to this outcome include:

- Downtime Reduction: By detecting potential issues early and scheduling maintenance proactively, the manufacturer avoided costly unscheduled stoppages and emergency repairs.

- Cost Savings: The decrease in downtime and emergency servicing lowered direct production losses and maintenance costs, freeing up resources.

- Extended Asset Lifespan: Planned maintenance enables better care of equipment, reducing wear and tear and prolonging asset life.

- Improved Compliance and Risk Management: Hardcat’s system maintains detailed maintenance histories and automation, supporting regulatory compliance and avoiding fines.

- Operational Efficiency: Enhanced visibility of asset health and maintenance status boosts technician productivity and streamlines resource allocation.

Hardcat’s EAM transforms maintenance from a reactive cost center to a strategic advantage, driving measurable ROI by leveraging predictive capabilities. This example underscores how predictive maintenance integrated with comprehensive asset management delivers concrete financial and operational benefits for global manufacturers, reinforcing reliability and competitiveness in their operations.

Extended asset lifespan

According to a study by ARC Advisory Group, enterprises that adopt preventive maintenance strategies see a 20–40% increase in asset lifespan.

EAM software helps enterprises maximise asset life by:

- Tracking detailed maintenance history and warranties

- Enforcing regular servicing intervals

- Managing refurbishments and component replacements

Example ROI Impact:

A leading logistics company significantly improved its asset performance by adopting Hardcat’s Enterprise Asset Management (EAM) solution, extending the useful life of its vehicle fleet by an average of 18 months. This strategic improvement enabled the company to avoid $1.2 million in premature replacement costs over a three-year period, delivering substantial financial and operational benefits.

By leveraging Hardcat’s EAM platform, the logistics company implemented proactive fleet maintenance, real-time monitoring, and accurate asset lifecycle tracking. This data-driven approach ensured vehicles were maintained at optimal performance levels, reducing mechanical failures and slowing asset wear and tear.

Key benefits that contributed to this outcome include:

- Extended Asset Lifespan: Optimised maintenance schedules and early detection of potential issues prevented unnecessary strain on vehicle components, adding an average of 18 months to fleet service life.

- Significant Cost Avoidance: Postponing premature replacements avoided $1.2 million in capital expenditure over three years, freeing funds for other business priorities.

- Enhanced Fleet Reliability: Better-maintained vehicles experienced fewer breakdowns, increasing delivery performance and customer satisfaction.

- Optimised Maintenance Planning: Automated scheduling based on real usage data ensured maintenance occurred exactly when needed, neither too early nor too late, maximising value from each asset.

- Improved Compliance and Safety: Detailed maintenance records and inspections supported regulatory compliance, reducing the risk of fines or safety incidents.

This case exemplifies how Hardcat’s EAM elevates asset management from a reactive, cost-heavy process into a proactive strategy that protects capital investment. Instead of simply replacing vehicles on a fixed schedule, the logistics company was able to base replacement decisions on accurate condition data, ensuring each asset reached its optimal lifecycle.

For logistics businesses and other fleet operators, these results demonstrate that an effective EAM solution is not just about keeping assets running, it’s about maximising their investment potential, improving reliability, and reducing the total cost of ownership.

Industry-wide, companies adopting similar EAM-led maintenance and lifecycle strategies regularly see fleet lifespans extended by 15–25% and savings in the millions, reinforcing that this approach delivers measurable ROI and long-term competitive advantage.

Improving compliance and risk mitigation

Non-compliance with health, safety, or environmental regulations can result in fines reaching $100,000+ per incident, not to mention reputational damage and legal fees.

EAM software automates compliance management by:

- Maintaining digital audit trails and certifications

- Sending alerts for inspections and license renewals

- Generating on-demand regulatory reports

Example ROI Impact:

A transportation provider avoided over $500,000 in penalties by maintaining accurate maintenance logs and inspection records in their EAM platform.

Optimising inventory

Optimising inventory for better working-capital management can deliver surprisingly strong returns. The average business holds 20–30% more inventory than needed, tying up capital and increasing storage costs (McKinsey).

EAM software helps by:

- Forecasting parts demand based on maintenance schedules.

- Managing stock levels and reorder thresholds.

- Linking procurement to asset usage data.

Example ROI Impact:

A public infrastructure authority reduced spare parts inventory by 22%, unlocking $350,000 in working capital without compromising availability.

Enhancing workforce productivity

Technicians can spend up to 25% of their time searching for information or tools. Organisations therefore need tools that help their workers collaborate and stay connected across geographies and functions. Digital collaboration tools are primed to play a critical role in enabling workers to tap into the collective knowledge of the enterprise, solve problems with experts remotely, and turn internet of things (IoT) data into lasting value (McKinsey).

EAM platforms eliminate this waste by providing:

- Mobile access to work orders and manuals

- Real-time asset location data

- Automated task assignments and time tracking

Example ROI Impact:

A logistics firm increased technician productivity by 25% after going mobile with EAM, enabling the same team to complete more tasks—worth $400,000 in annual labour efficiency gains.

Strategic capital planning

With accurate lifecycle and performance data, enterprises can better plan capital expenditures. According to IBM, data-driven asset strategies can reduce capital spending by 15–25%.

EAM helps organisations:

- Predict asset degradation and replacement timelines

- Identify underperforming assets for decommissioning

- Prioritise capital investments aligned with operational goals

Example ROI Impact:

A global energy company used EAM data to phase out inefficient assets, saving $700,000 in operating expenses and deferring $2 million in capital investment.

Data-driven decision making

Asset-related decisions can no longer be based on gut feeling. Gartner reports that organisations using advanced analytics outperform peers by 20% in asset optimisation metrics.

EAM software supports strategic decisions with:

- Dashboards and KPIs like MTBF (Mean Time Between Failures) and asset utilisation

- Maintenance cost trend analysis

- Performance benchmarking across locations or asset types

Example ROI Impact:

An international logistics company identified a single underperforming asset type that consumed double the maintenance budget. Eliminating it saved over $500,000 annually.

Scalability and integration across systems

Scalability and integration represent foundational pillars of effective asset management software solutions, especially as organisations experience growth and increased operational complexity. This ensures that as enterprises expand their asset portfolios, their management systems can seamlessly accommodate this growth without performance degradation or functional limitations, effectively future-proofing their technological infrastructure.

Simultaneously, integration capabilities serve as the crucial connective tissue of modern enterprise asset management, enabling the harmonious compilation and synthesis of data from diverse sources to create a unified operational picture.

Today’s sophisticated EAM platforms demonstrate this integration prowess by connecting seamlessly with ERP systems to align asset management with broader financial and procurement operations, incorporating IoT sensor networks to enable real-time monitoring and condition-based maintenance strategies.

This comprehensive integration ecosystem changes siloed data repositories into a cohesive information architecture that supports informed decision-making, optimises asset lifecycles, and ultimately drives organisational value through improved operational efficiency and reduced total cost of ownership.

Modern EAM platforms integrate with:

- ERP software for finance and procurement alignment

- IoT sensors for real-time asset monitoring

- GIS and BIM systems for spatial data integration

Example ROI Impact:

A report by Deloitte found that integrated asset management systems improve operational efficiency by 18–30%. A multi-site food processing company integrated EAM with IoT and reduced maintenance costs by 18% within the first year through more accurate failure prediction and faster response.

Conclusion: EAM as a Smart Investment

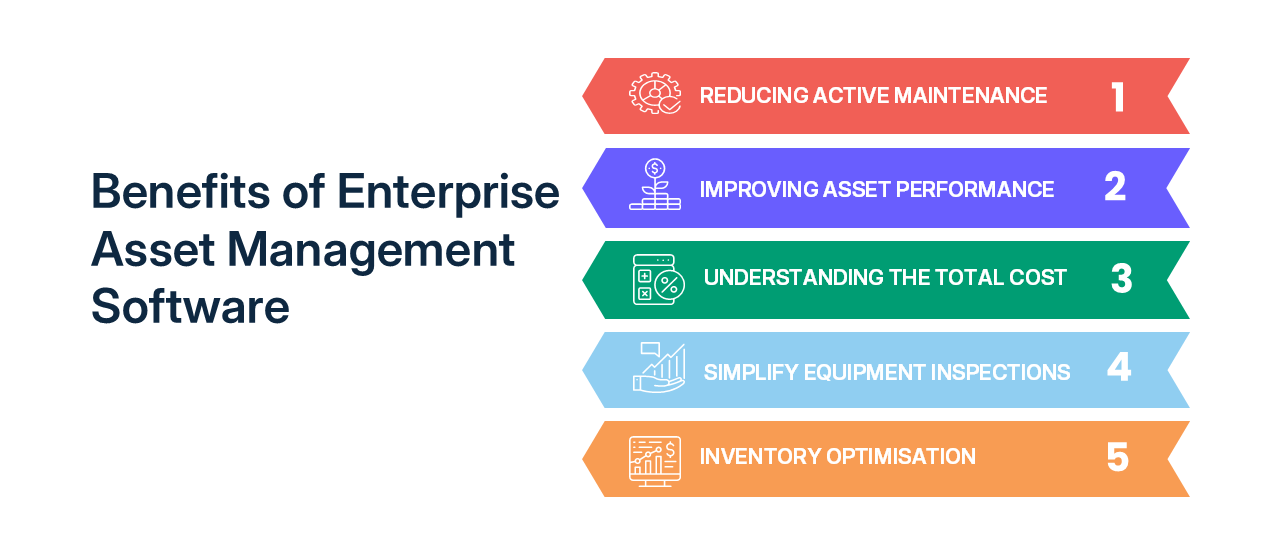

Enterprise Asset Management software is no longer just a tool for maintenance managers—it’s a strategic investment that delivers measurable ROI across the business. From extending asset life and reducing downtime to boosting compliance and streamlining capital planning, EAM helps enterprises cut costs and work smarter.

Asset managers can find boundless opportunities. But they must abandon “that’s how we’ve always done things.” They need to help shape what comes next. Solution providers such as Hardcat can improve asset visibility, cost control, and performance for both enterprises and SMEs. They can do this by integrating with your existing software and overcoming adoption challenges.

Quick Stats Recap:

- 30% reduction in downtime with predictive maintenance

- 20–40% longer asset lifespan with EAM sustainability practices

- 25%+ boost in technician productivity

- 15–25% reduction in capital expenditure through smarter planning

- 18–30% operational efficiency gain with integrated asset systems

Ready to see how EAM can elevate your asset strategy?

Elevate your maintenance operations from a cost centre to a strategic advantage. Schedule your personalised Hardcat EAM platform demonstration today and see the ROI potential first-hand.

Contact Hardcat’s expert team to explore solutions that deliver real ROI—fast, scalable, and tailored to your enterprise needs.